Myco-Shell Upcycling

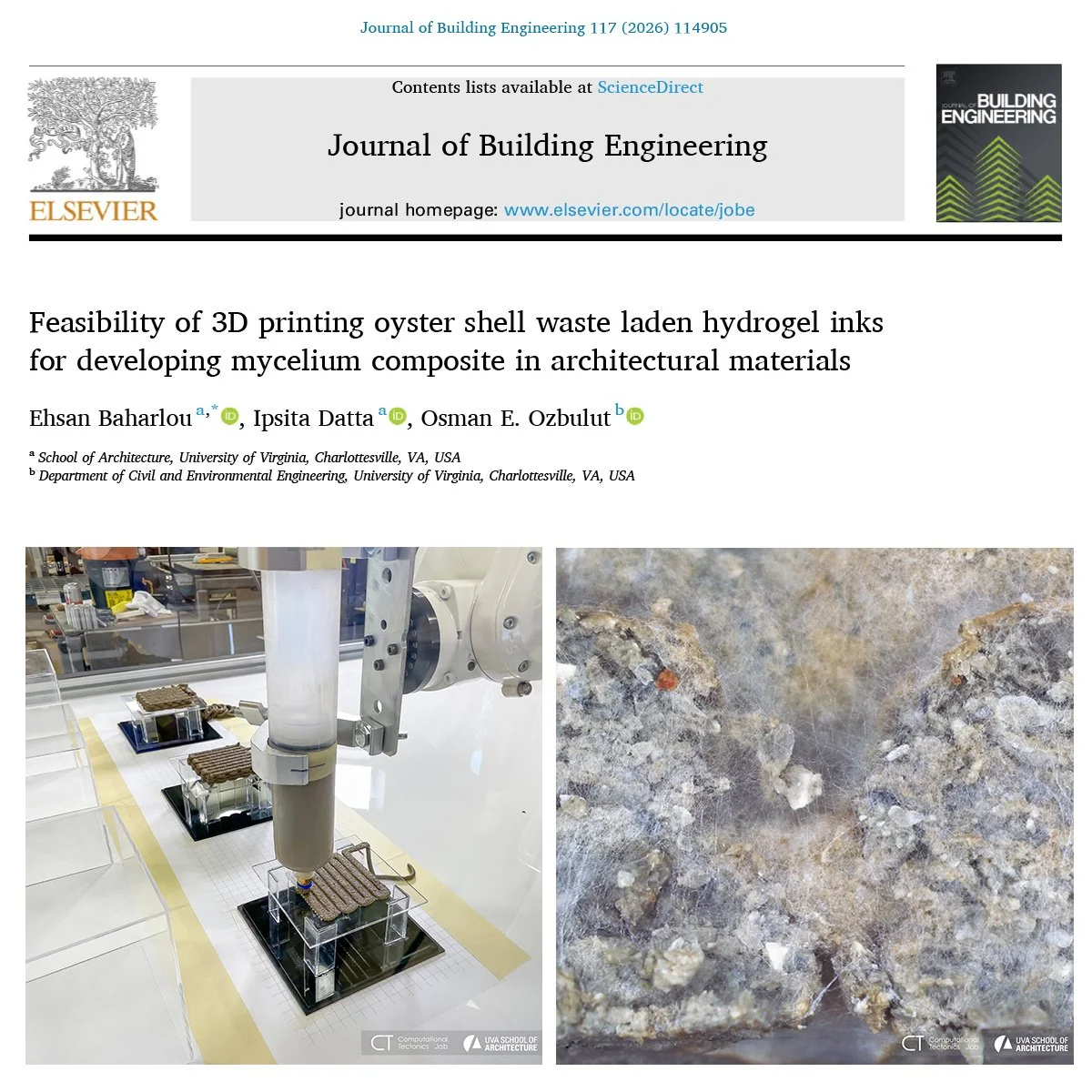

This study explores the feasibility of utilizing upcycled oyster shell (OS) waste in mycelium-based additive manufacturing to develop sustainable bio-composite materials. OS waste, predominantly composed of calcium carbonate, is generated in large volumes by the seafood industry and often ends up in landfills; its reuse provides both a circular material pathway and a mineral-rich scaffold that can influence fungal growth. It investigates the biocompatibility of mycelium growth on OS-based substrates and optimize the nutritional conditions required for its propagation. A printable composite ink is formulated by incorporating OS waste as a structural scaffold, ensuring both printability and mechanical stability for extrusion-based 3D printing. The rheological properties, shrinkage behavior, and viscoelastic characteristics of the composite ink are assessed to demonstrate the suitability of the composite inks for additive manufacturing applications. Experimental findings demonstrate that 5 wt.% Potato Dextrose Agar (PDA) concentration achieves an optimal balance between radial and sectional mycelium growth. Indirect inoculation using surface-placed mycelial plugs further enhances colonization within 3D-printed cross-ply grid structures, particularly those with wider (3 mm) line gaps. However, full integration of mycelium within the printed layers remains a challenge, indicating the need for further substrate optimization and controlled environmental conditions. This research contributes to the advancement of mycelium-based bio-composites in sustainable construction, offering a scalable approach for repurposing agricultural waste into regenerative and circular architectural materials.

The full paper is available in the Journal of Building Engineering.

Project Team: Ehsan Baharlou, Ipsita Datta and Osman Ozbulut, University of Virginia