Toolpath-Informed Biofabrication:

Architecturing Mycelium-Mineral Composite Panels

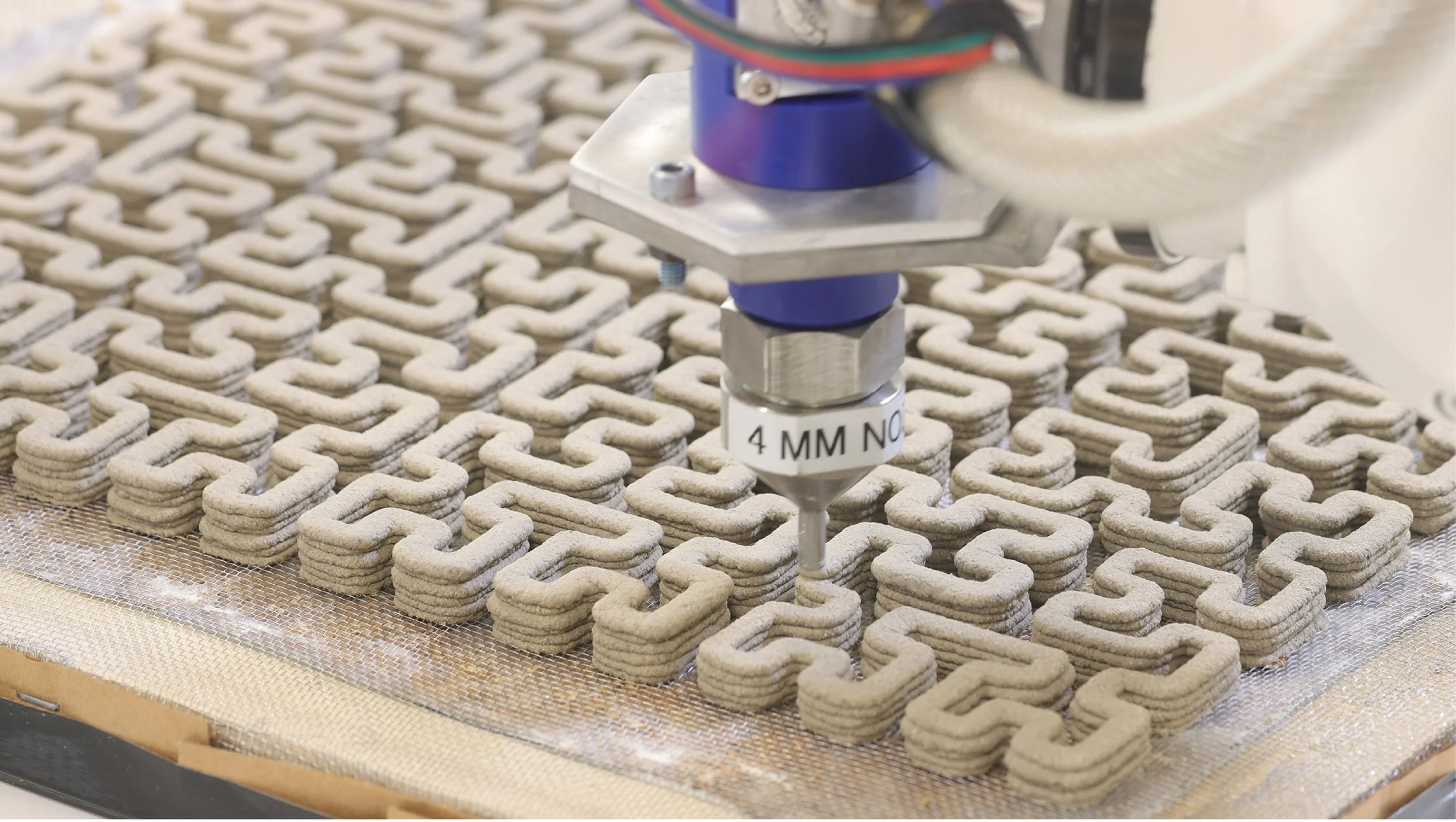

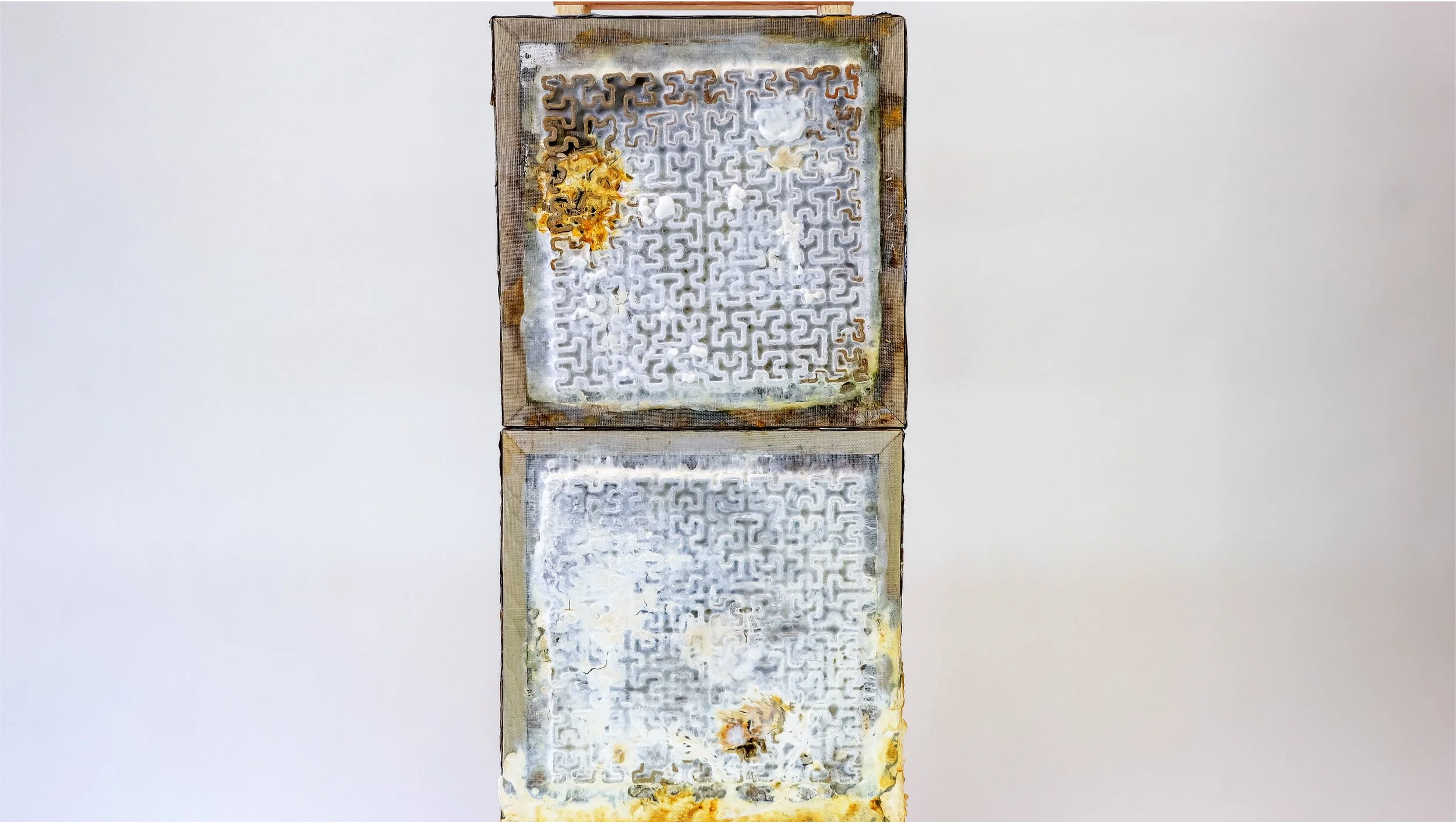

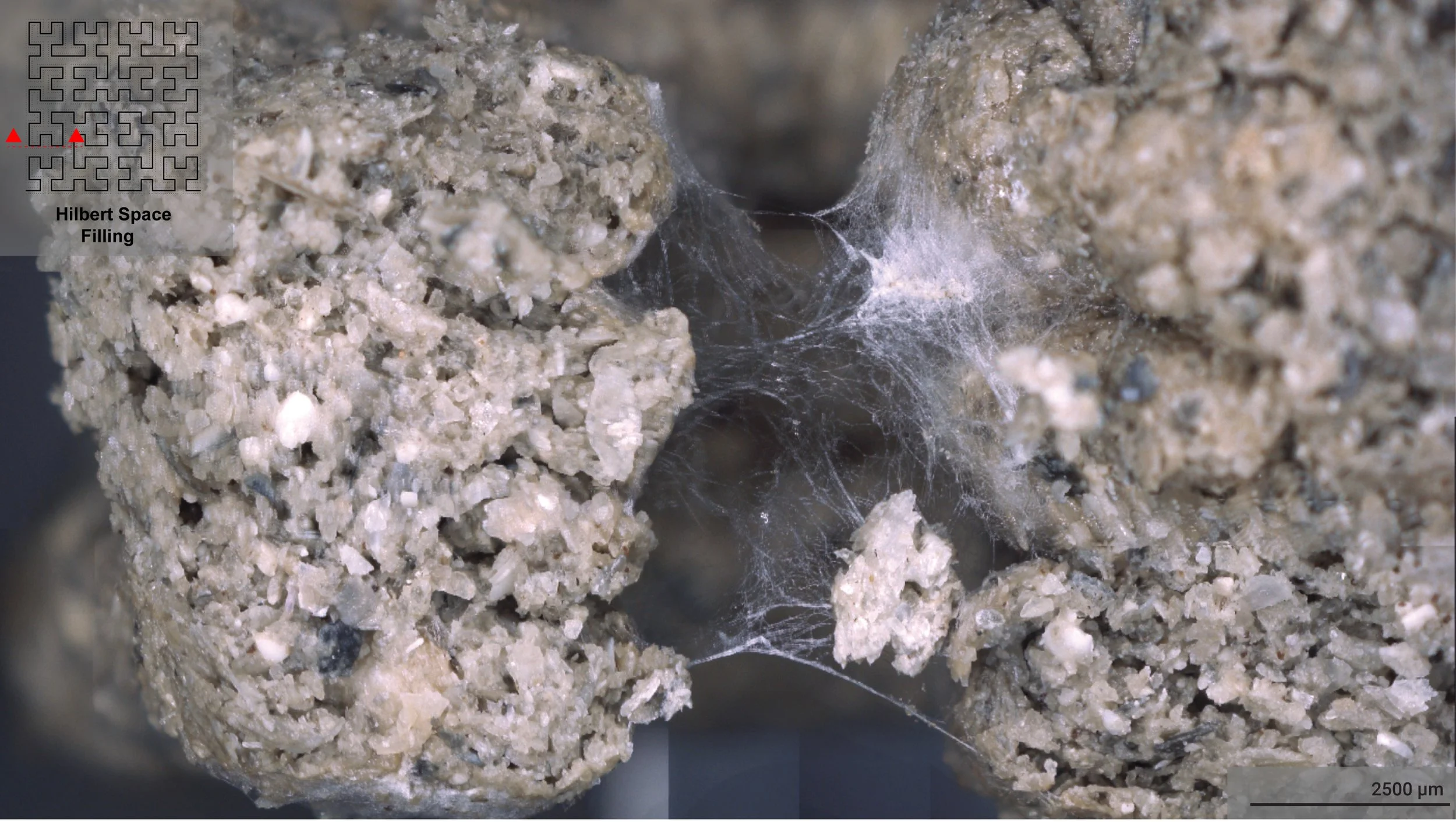

Building on the successful analysis and testing of OS biocomposite ink and robotic extrusion–based fabrication, the biocomposite inks were applied to architectural–scale composite panels. A toolpath–informed biofabrication strategy was developed to guide fungal colonization within OS composites, focusing on the role of spatial geometry in enabling aerial mycelial growth without lignocellulosic substrates. A series of filling toolpath strategies were created and tested at small scale. Among the patterns tested, the Hilbert geometry demonstrated the highest colonization rates due to its symmetrical spacing and continuous path logic.

To scale up this approach, updated paste extruders mounted on the robot precisely printed the paste onto a custom indirect inoculation kit. This kit, combined with custom–built controlled incubation conditions, allowed mycelium to propagate from a living substrate into the printed scaffolds. High–resolution microscopy confirmed consistent hyphal bridges across layers, showing that geometric porosity and local oxygen drive growth even without lignocellulosic feedstock.

Treating tool–paths as biological interfaces reframes fabrication: growth becomes spatially programmed, not chemically embedded. The study provides a scalable framework for integrating living materials into construction by coupling digital tool–path design with metabolic control.

This project was presented at ACADIA 2025 Conference at Florida International University, Miami.

Project Team: Ehsan Baharlou, Ipsita Datta and Ye Ma, School of Architecture, University of Virginia